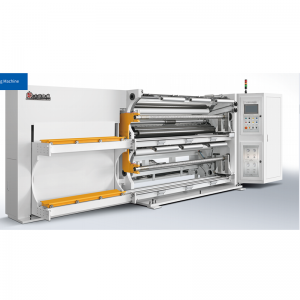

SLM-B Babban Gudun Wuta ta atomatik

1.This inji ne yafi amfani da yanke takarda, laminated film, aluminum tsare, da dai sauransu.

2.Entire na'ura yana sarrafawa ta hanyar PLC (motoci biyu na vector), ƙirar mutum-machine, aikin taɓa allo.

3.Unwinder part equip tare da Italiya RE iska birki, gane da PLC atomatik kirgawa, kazalika da m tashin hankali iko ga unwinding.

4.Transmission part yana amfani da vector mita hira mota, gane da m line gudun iko.

5.Unwinder shaftless.tare da na'ura mai aiki da karfin ruwa auto loading, mataimakin-clamps lantarki.

6.Re winders ana sarrafa su ta hanyar motoci, Cikakken na'urar kashewa ta atomatik hade da na'ura.

7.Auto mita presetting, auto mita kirgawa, auto tsayawar, da dai sauransu.

8.EPC na'urar gyara kuskure yana da kyau don tabbatar da daidaito.

| Matsakaicin nisa na abu | 1200-2500mm I |

| Matsakaicin diamita mara iska | Φ1000/1300mm |

| Matsakaicin diamita mai juyawa | 6600mm |

| Gudu | 450-600m/min |

| Ƙarfi | 13 kw |

| Gabaɗaya girma (LX WX H) | 1800X2800X1600mm |

| Nauyi | 5500kg |

Slitter mai sauri ta atomatik ƙwaƙƙwarar injuna ce da aka ƙera don yanke manyan nadi na kayan zuwa ƙarami, mafi faɗin faɗin sarrafawa.Yana ba da fa'idodi masu mahimmanci akan hanyoyin yankan hannu, gami da haɓaka yawan aiki, ingantaccen daidaito da rage sharar gida.Bari mu zurfafa duban fasali, fa'idodi da aikace-aikacen wannan na'ura mai ban mamaki.

High-gudun atomatik slitters san su na kwarai yankan gudun.Tare da ci-gaba da fasahar mota da madaidaicin tsarin sarrafawa, za su iya cimma saurin gudu har zuwa mita 1000 a cikin minti ɗaya, wanda ya zarce ƙarfin hanyoyin gargajiya na gargajiya.Wannan ƙarfin saurin sauri yana ba da damar sarrafa sauri na manyan kundin kayan aiki, adana lokaci da farashin aiki.

Ɗaya daga cikin manyan fasalulluka na slitter ta atomatik shine ikon yin aikin tsagawa ta atomatik.Wannan yana nufin cewa da zarar an saita na'ura kuma an tsara shi zuwa girman da ake so, za ta iya ciyarwa, yankewa da iska ta atomatik ba tare da sa hannun ɗan adam akai-akai ba.Wannan ikon sarrafa kansa yana 'yantar da albarkatun ɗan adam mai mahimmanci, yana bawa mai aiki damar mai da hankali kan wasu mahimman ayyuka yayin da injin ke aiki tuƙuru don yin aikin da aka ba shi.

Daidaituwa yana da mahimmanci a cikin tsarin masana'antu, kuma masu tsattsauran ra'ayi ta atomatik suna ba da daidaici na musamman.An sanye shi da na'urori masu auna firikwensin zamani da sarrafawa, waɗannan injunan suna iya ci gaba da cimma nasarar yanke juriya gwargwadon ± 0.1mm.Wannan matakin madaidaicin yana tabbatar da daidaito a cikin samfurin ƙarshe, haɓaka inganci da gamsuwar abokin ciniki.

Wani muhimmin fa'ida na slitters ta atomatik shine ikonsu na rage sharar kayan abu.Hanyoyin yankan hannu na al'ada sukan haifar da babban ragi da yankewa, yana haifar da ƙarin farashin kayan aiki da haɓaka tasirin muhalli.Sabanin haka, slitters na atomatik suna haɓaka amfanin kayan aiki ta hanyar rage faɗin nadi don dacewa daidai girman da ake buƙata.Rage sharar gida yana adana farashi kuma yana ba da gudummawa ga dorewar tsarin masana'anta.

Filayen aikace-aikace na injunan tsagawa na atomatik masu sauri suna da faɗi da bambanta.A cikin masana'antar takarda, ana amfani da waɗannan injina don canza manyan nadi na takarda zuwa kunkuntar nisa bisa ga takamaiman buƙatu.Masu sana'ar fim suna amfani da slitters ta atomatik don aiwatar da manyan nadi na fim zuwa ƙananan nisa don marufi ko bugu.Hakazalika, masana'antun masana'anta da masana'anta suna amfani da wannan fasaha don yanke masana'anta zuwa ɗigo ko nadi masu dacewa da kera tufafi.Hatta masana’antar sarrafa karafa sun amfana da tsage-tsalle masu sarrafa kansu, ta yin amfani da su wajen yanke igiyoyin karfe zuwa kunkuntar filaye don aikace-aikace iri-iri.